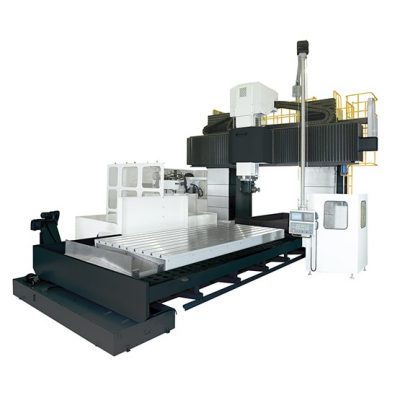

description

| table size: | 7.9” (200mm) round |

| travel (x, y, z): | 18.1” x 20.1” x 18.1” (460 x 510 x 460mm) |

| travel (a, b): | -120 to 30 deg. /0~360 deg. |

| spindle taper: | nst no. 40 |

| spindle speed: | 200~20,000rpm |

| tool storage capacity: | 174 pcs. (230,258,314 opt.) matrix style |

| tool change time (t-t/c-c): |

1.3 sec. /2.5 sec. |

| rapid feed (x, y, and z): |

2,362ipm (60m/min) |

| rapid feed (a, b): | 18,000 deg./min (50rpm) |

| power requirement: | 55kva |